Tipping the Scales

A conference about accelerating the right kinds of impact

Hi everyone,

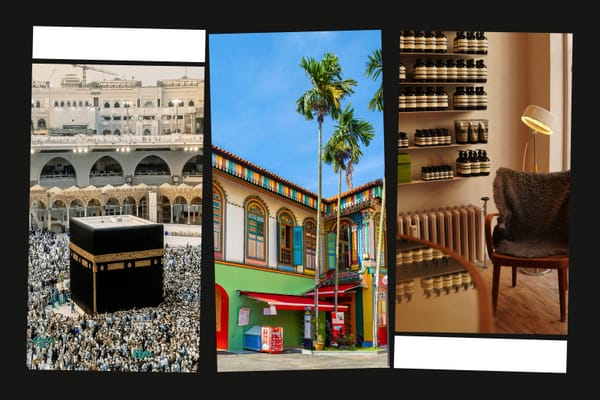

This week, a report from Azure Magazine’s inaugural Human/Nature conference, held last week in Toronto. With a mix of local and international participants, it offered an invigorating set of conversations around sustainability and design.

Happy Halloween! I’m up to my usual trick: buying candy to give away at the door, then going out with my kids instead so that I have a full bag to return home to. 😈

The more you know,

Brian

🔗️ Good links

- 🏢👀 Buildings that caught my eye: Fokkema & Partners and Broekbakema’s energy-neutral office building in Maastricht (links in firm names); Office Kersten Geers & David Van Severen’s library in small-town Belgium; Quinzhee’s “double” mountain chalet 90 minutes east of Montreal; Branco del Rio’s long, narrow office building in a repurposed metal workshop; 3Xn’s in-progress Sydney Fish Market, subject of another Human/Nature conference keynote

- 😎🌍 South Africa’s “story of rapid, invisible [solar panel] growth is being repeated across the continent.”

- 🖼️🏦 Andrea Fraser’s “2016 in Museums, Money, and Politics” is now available online for free

- 👨🏻💻🌆 Colin Marshall reviews a new book about “How the Texas capital became too expensive, too ambitious, and too hot for its slackers”

- 🚴🏻♂️🚴🏻♀️ “Here we estimate and map routes for every Bike Share trip in Toronto in June 2024. There were 762,760 trips in total!”

- 💦🇲🇽 My fascination with Mexico City’s water crises continues. “What saved [its]] residents from a calamitous water-system collapse was a combination of just-in-time rainfall, urgent political pressure and underground reserves that saw the city through the worst.”

Tipping the Scales

Last Thursday, as Julia Watson of the Lo–TEK Institute outlined one inspiring project after another in her Human/Nature conference opening keynote, I began wondering to myself, “Just how big are these initiatives?” The event, Azure magazine’s first gathering on “climate change mitigation in architecture and design,” prompted many reflections on scale. In design industries that have fundamentally accepted the realities of climate change, the question is no longer, “Do we need to do something?” It’s: “How do we have the most impact in the least amount of time?” Are the crises we face best combated by appealing to hearts and minds through aesthetic choices, exploring new materials and technologies, or ironing out inefficiencies in the building process? The answer, of course, is some combination of all three, and the day’s speakers offered up projects and products that tackle our challenges from each angle.

Watson was previewing her forthcoming Lo–TEK Water, the sequel to her 2019 book chronicling “Local and Traditional Ecological Knowledge.” From her own forthcoming case-study house that transmits disappearing Danish seagrass-thatching techniques to an Indigenous kelp-harvesting program on New York’s Long Island, she hopped across the globe with inspiring stories about projects that are “living, coevolutionary, co-energetic, symbiotic, and cyclical.” Having identified them, the next question in my mind: “How do we bring them to more people?”

In the afternoon, a panel on sustainable, affordable housing included the phrase “scaling up” in its title. David MacMillan, of the City of Toronto’s Environment & Climate Division, was forthright with numbers, both in explaining the progress the city has made toward its environmental targets and the need to accelerate that progress if it’s going to meet those goals. In detailing a handful of sites where the city will develop housing, a story emerged that speed and sustainability go hand-in-hand. Mass timber, when paired with prefabrication, is often the most cost-effective solution—at least at the largest and smallest scales.

The in-between, what panelist Jonathan Diamond of Well Grounded Real Estate described as “mid-market mid-rise,” is, according to the City, still most affordably built with steel. Diamond shared a current project in the city’s east end that addresses that “missing middle” more sustainably. His mantra was efficiency: a prefabricated hybrid-timber system uses components from an Austrian company to deliver a building that is more assembled than constructed, with a high-performing outcome achieved in something like one eighth of the typical construction time. His mantra: “We’re not density maximizers, we’re efficiency maximizers.”

In a rapidly growing city like Toronto, that’s an appealing message, not least because he went on to say his company is beginning to “think about scale not at the building level, but at the project level,” finding ways to combine plots and build multiple structures without succumbing to the generic podium-and-tower configuration so prevalent here.

Yet the conversation that sticks with me most comes from a morning panel with designers working at a very small, and very local, scale: Stephanie Lipp, who has designed a leather alternative using mycelium; Justin Beitzel, who is designing furniture and products that “give back more than they take”; and Caroline Cockerham, whose company makes wool rugs in a circular process with local supply chains . After their conversation, an audience member asked, “Right now, companies like Chanel are on Fifth Avenue in Manhattan. How do we get companies like yours there instead?” The panelists gently redirected the impulse, suggesting that sprawling supply chains of the kind that support global flagships are part of the problem. You can’t connect your materials all the way back to the land; investor scale “is not compatible with human scale or the natural scale, the circularity that benefits us all.”

Rather than ten companies lined up on Fifth Avenue selling thousands of products, I came away from the conversation with an inspiring image: thousands of companies, dispersed across the globe, each selling ten products. Horizontal scale rather than vertical, and companies growing organically—an apt term—rather than exponentially. Beitzel’s company is based in Baltimore, but he asked, “What would the Oka chair [we designed] look like if it was made in Southern California?” The question suggests a world in which each region showcases its own craft skills and its own “bioregional acumen,” making use of locally accessible materials in ways that, of necessity, generate regional aesthetics. I’d invest in that.